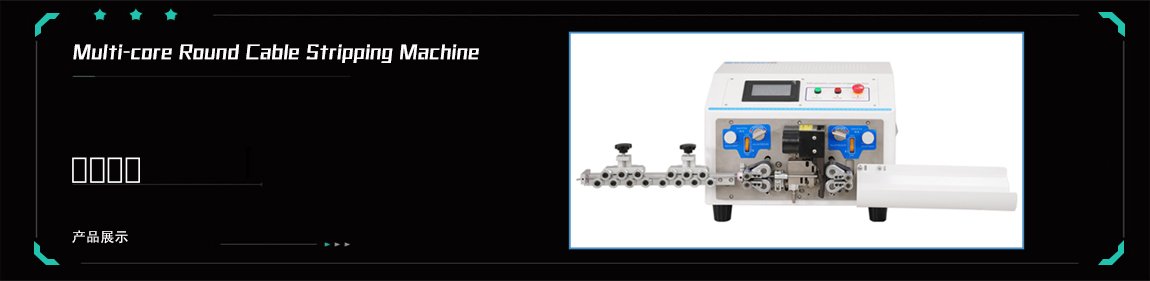

This is an economical multi-core sheath wire stripping machine. It can strip the core wire after the outer sheath is stripped. It has powerful functions and is suitable for processing sheath wires within 6 cores. The blade holder adopts a double-blade structure. The round blade is used for stripping the outer sheath, and the flat blade is used for stripping the core wire. The blade holder automatically shifts to switch the appropriate blade. There is a workbench at the bottom of the machine and it is equipped with universal casters for easy movement.

The belt feeding is used to replace the traditional roller feeding, which greatly increases the contact area with the wire. While increasing the tension and enhancing the stripping ability, it can also reduce the pressure and reduce the damage to the surface of the wire sheath, and there is no indentation on the surface of the wire sheath. The blade holder is driven by a high-precision servo motor, which is fast and powerful.

The upper and lower sets of wire feeding wheels are driven by positive and negative screw rods, which can be opened and closed at the same time. When processing wires of different thicknesses, the position of the centerline of the wires can always be kept unchanged, and the wires are always aligned with the center of the knife edge, which can effectively prevent the stripping from tilting. The pressure of the wire feeding wheel can be set directly in the program, no need to manually adjust the screw, it is very convenient to switch between different wire diameters.

This machine also has the function of automatic pulley and jump guide. The automatic pulley means that the outlet pulley can automatically open for avoidance when stripping the wire head. The jump guide function means that when the end of the wire is stripped, the wire inlet conduit is automatically lifted to avoid it, which greatly increases the stripping length range.

The program memory function can store the processing parameters of different wires into different program numbers, and can save up to 100 groups of programs. When processing the wire again, the corresponding program can be called out with one key. One machine can complete the processing of various types of wires, which is very versatile.

Applicable wire core area: 2~70mm2

Number of sheathed core wires: ≤6 cores

The largest diameter of the catheter: Φ16mm

Cutting length: 0~100m

Cutting tolerance: ±(0.5+L*2‰)mm (L=cut length)

Maximum stripping length of the outer sheath: wire head 500mm, wire tail 100mm

Core wire stripping length: 0~50mm

Cutter Motor: Servo Motor

Feeding motor: stepper motor

Operation interface: 7-inch color touch screen

Program memory: up to 100 programs can be saved

Production efficiency: 800 pieces/hour

Working voltage: 220V 50Hz

Net weight: 100kg

Dimensions: 700*600*1100mm

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

English

English