Stable performance and low failures;

Adjustable parameters according to different requirements;

Reasonable space design and centralized functions;

High quality LCD display screen;

Easy to program and operate;

Designed by human structural mechanics to reduce fatigue strength;

Both feeding rollers and cutting unit are driven by servo motor;

The program memory function can store the processing parameters of different wires into different program numbers, and the corresponding program can be called out with one key when processing the wire again. One machine can complete the processing of various wires, which is very versatile;

The knife holder adopts a double-blade structure, and 2 sets of blades are installed on the bladeholder. The program can specify which set of blades to use to perform the current process, so different blades can be used for cutting and stripping. For example, use a V-shaped blade to cut, and use a round-shaped blade to strip the wire, which will not affect the cutting life of the blade and ensure the stripping effect;

The upper and lower sets of wire feeding wheels are driven by positive and negative screw rods, which can be opened and closed at the same time, when processing wires of different thicknesses. The position of the center line of the wire can always be kept unchanged, and the wire is always aligned with the center of the knife edge, which can effectively prevent the inclination of the stripping edge. The pressure of the wire feeding wheel can be set directly in the program, no need to manually adjust the screw, it is very convenient to switch between different wire diameters;

This machine also has the function of automatic lifting wheel and jump guide. The automatic lifting wheel means that the outlet wheel can automatically open for avoidance when stripping the wire head, and the jump guide function means that when the tail of the wire is stripped, the wire inlet guide is automatically lifted for avoidance, which greatly increases the stripping length range;

The wire feeding mechanism uses an extended pulley to feed material, which greatly increases the contact area between the wire and the wire feeding wheel. lt can ensure no slippage when processing large cables, provide sufficient power for stripping wires, and at the same time reduce pressure and reduce damage to wire sheaths, and there is no indentation on the surface of wire insulation;

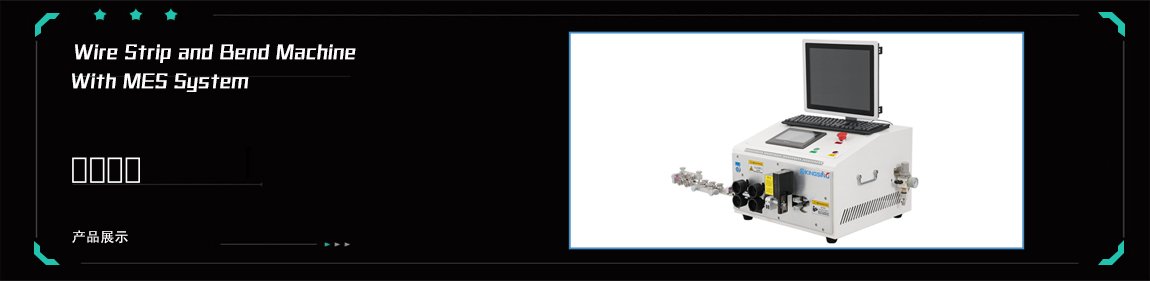

Optional computer industrial control system (Windows operation interface), supports MES system and document import, remote order dispatch, automatic coding, etc.

| Model | Applicable core area | Features |

|---|---|---|

KS-W6211A | 10 ~ 300mm² | 300mm² standard model |

KS-W6211B | 10 ~ 300mm² | With rotary blade stripping function |

KS-W6211S | 10 ~ 300mm² | With piercing and scribing function |

KS-W6211R | 10 ~ 300mm² | With automatic winding and retracting wire function |

| KS-W6211D | 10 ~ 400mm² | 400mm2 enlarged type |

| 10 ~ 300mm² | MES system wire stripping machine ,with winding function |

Max cutting length: 1000 meters

Cutting accuracy: 0.002*L (L=cutting length)

Max stripping length: wire head 1000mm, wire tail 300mm

The largest diameter of the catheter: Φ42mm

Motor type: all use servo motor

Operation interface: 10-inch color touch screen

Program saving: up to 100 groups of programs can be stored

Winding and retracting the wire: the winding machine is optional, and the standard machine does not include the looping function

Optional configuration: computer industrial control system supporting MES

Net weight: 750kg

Dimensions: 1720*700*1290mm

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

The looping wire collection function is shown in the figure below, the leftmost one is the looping wire collection machine:

English

English