Stable performance and low failures;

Adjustable parameters according to different requirements;

Reasonable space design and centralized functions;

High quality LCD display screen;

Easy to program and operate;

Designed by human structural mechanics to reduce fatigue strength;

With program memory function, can store up to 100 groups of programs;

lt can process two wires at the same time, and the production efficiency is high;

Adopts belt feeding instead of traditional roller feeding, which greatly increase the contact area with the wire, while increasing the tension and enhancing the stripping ability, it can also reduce the pressure and reduce the damage to the surface of the wire sheath;

The blade carrier is driven by high-precision servo motor, which is fast and powerful;

The pressure of the wire feeding belt can be set directly in the program, no need to manually adjust the screw, it is very convenient to switch between different diameters;

Optional with coiling machine, long wire conveyor belt, slitting, inkjet, laser marking and other functions.

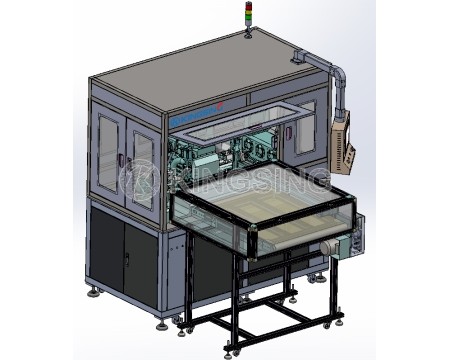

Applicable wire diameter: single wire 2~70mm2, double wire 2~25mm2

The maximum diameter of the catheter: the maximum diameter of a single wire is Φ25mm;the maximum diameter of a double wire is Φ12mm

Full stripping length range: wire head 0~220mm, wire tail 0~100mm

Maximum half-stripping length: wire head 1000mm, wire tail 400mm (according to wire material)

Minimum glue retention length: 120mm

Maximum cutting length: 1000m

Laser marking machine: UV laser marking, wavelength 355nm

Operation interface: 7-inch color touch screen (optional with industrial control computer system)

Program saving: up to 100 groups of programs can be stored

Cutting accuracy: 0.002*L (L refers to the length of the cutting wire)

Working voltage: 220V 50/60Hz

Stripping machine size: 1100*630*1150mm

Stripping machine weight: 239kg

Laser marking machine size: 1110*890*1690mm

Laser marking machine weight: 130kg

Laser machine water tank size: 600 * 300 * 530mm

Weight of water tank of laser machine: 27kg

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

English

English