This machine has a built-in automatic wire feeding machine, which supports bulk wire and reel-loaded wire. It can synchronously feed the wire for the wire stripping machine and maintain a stable wire feeding tension, which can effectively solve the problems of scattered and knotted wires. The stable tension is also conducive to improving the processing accuracy. The wire feeding machine is integrated in the workbench, which occupies a small area, and the waste wire sheaths will be automatically collected into the top drawer, which can keep the working environment tidy.

This machine can also be equipped with a wire taking robot and a conveyor belt, which will be very useful when processing long wires longer than 1 meter. It can put the wires straight and neatly into the receiving tray instead of falling directly on the ground and making a mess . The standard length of the conveyor belt is 2 meters, which is generally suitable for processing wires with a total length of less than 2.5 meters. We can also customize longer conveyor belts according to customer needs.

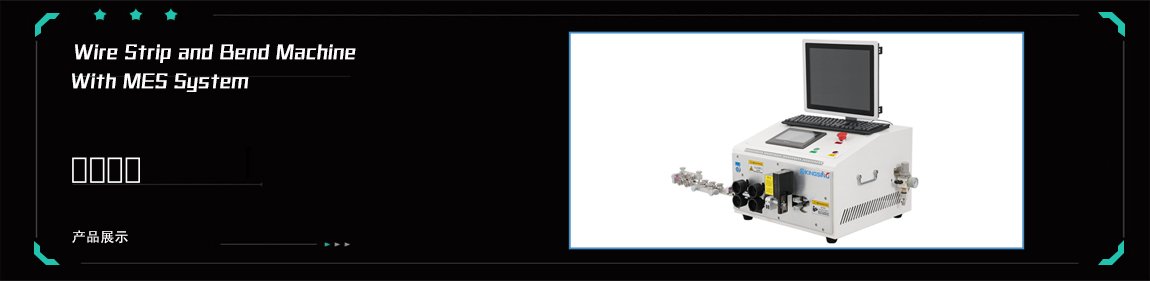

The program is powerful and supports functions such as full stripping, half stripping, and middle stripping. With the program memory function, the processing parameters of different wires can be saved in different program numbers, and the corresponding processing parameters can be called out with one key when switching wires.

The program interface is intuitive and easy to understand. Parameters such as cutting length, stripping length, cutting depth, retracting and output can be set freely in the program. Functions such as long wire program, ultra-short wire program, middle stripping program, and sheath wire program can be switched at will, and one machine supports many different processing methods, which is very versatile.

Applicable wire core area: 0.1 ~ 10.0mm² (AWG28~7)

Maximum catheter diameter: Φ10.0mm

Cutting length range: 0~100m

Cutting length accuracy: ±0.002×L (L means cutting length)

Stripping length range: wire head 0~120mm, wire tail 0~35mm

Minimum glue length: 35mm

Program memory function: up to 100 groups of programs can be saved

Working voltage: 220V/50Hz

Rated power: 430W

Air pressure: 0.4~0.6Mpa

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

English

English