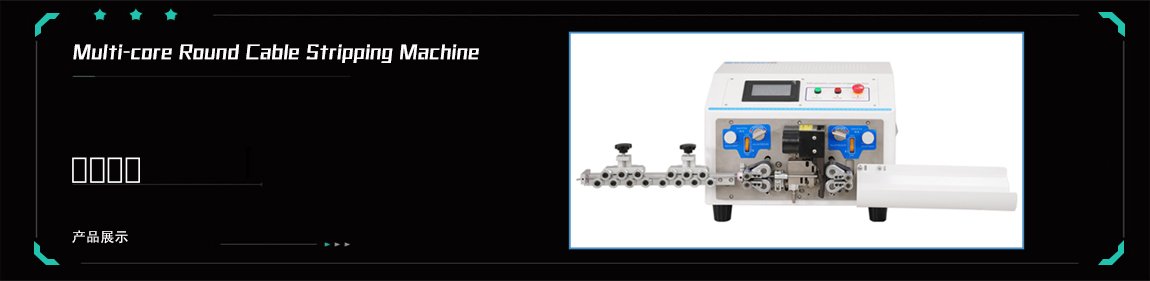

This is a multi-core sheath wire stripping machine with automatic winding and receiving function. It supports stripping the outer sheath and core wire, and can wind the processed wire into a circle. The blade holder adopts a double-blade structure. The round blade is used for stripping the outer sheath, and the flat blade is used for stripping the core wire. The blade holder automatically shifts to switch the appropriate blade. In addition to processing sheathed wire, this machine can also be used to process ordinary wire. When the coiling function is not needed, the coiling machine can also be turned off.

The belt feeding is used to replace the traditional roller feeding, which greatly increases the contact area with the wire. While increasing the tension and enhancing the stripping ability, it can also reduce the pressure and reduce the damage to the surface of the wire sheath, and there is no indentation on the surface of the wire sheath. The blade holder is driven by a high-precision servo motor, which is fast and powerful.

The upper and lower sets of wire feeding wheels are driven by positive and negative screw rods, which can be opened and closed at the same time. When processing wires of different thicknesses, the position of the center line of the wires can always be kept unchanged, and the wires are always aligned with the center of the blade opening, which can effectively prevent the stripping opening from tilting. The pressure of the wire feeding wheel can be set directly in the program, no need to manually adjust the screw, it is very convenient to switch between different wire diameters.

This machine also has the function of automatic lifting wheel and jump guide. The automatic lifting wheel means that the outlet wheel can be automatically opened for avoidance when stripping the wire head, and the jump guide function means that the wire inlet conduit is automatically lifted for avoidance when stripping the tail of the wire, which greatly increases the stripping length range.

The program memory function can store the processing parameters of different wires in different program numbers, up to 100 groups of programs can be saved, and the corresponding program can be called out with one key when processing the wire again. One machine can complete the processing of various types of wires. Very versatile.

Support non-standard customization, we have strong research and development capabilities, and can customize special functions according to customer needs. Common optional features include:

Install a safety shield, and automatically alarm and stop after opening the shield.

A scribing jig can be added. For wires with a long stripping length and a tight sheath, the scribing jig can be used to split the wire sheath on both sides to reduce the stripping resistance.

Add inkjet printers, wire number hot stamping machines and other equipment to realize coding while stripping wires.

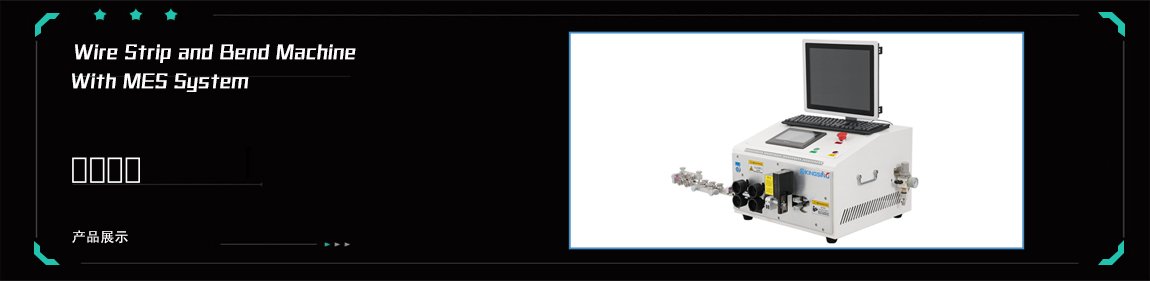

Optional computer industrial control system (Windows operation interface), supports MES system and document import, remote order dispatch, automatic coding, etc.

Main functions: stripping the outer sheath, stripping the core wire

Optional functions: core wire twisting, middle stripping and scribing, automatic coding, etc.

Applicable wire core area: 1~30mm2 (AWG18~2)

Full stripping length range: thread head 0~120mm, thread tail 0~80mm

Maximum half-stripped length: wire head 1000mm, wire tail 350mm (according to wire material)

Maximum cutting length: 100m (longer can be customized)

Operation interface: 7-inch color touch screen

Program saving: up to 100 groups of programs can be stored

Machine Appearance: Multiple options (same function, but different appearance)

Cutting accuracy: 0.002*L (L refers to cutting length)

Working voltage: 220V 50Hz

Rated power: 1000W

Note:

In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

English

English